Metal Copper Clad Laminate

Top Aluminum CCL Manufacturer OEM/ODM PCB Substrate Solutions

Metal Copper Clad Laminate

Top Aluminum CCL Manufacturer OEM/ODM PCB Substrate Solutions

About Metal Copper Clad Laminate

| Item | Test Method | EM-301 | EM-302 | EM-302H | EM-303 | EM-303H | EM-305 | EM-310 |

|---|---|---|---|---|---|---|---|---|

| (W/m·k) Thermal Conductivity |

ASTM D-5470 | 1.2 | 1.8 | 2.2 | 2.8 | 2.8 | 3.5 | 10.0 |

| (°C/W) Thermal Resistance |

ASTM D-5470 | <0.5 | <0.2 | <0.11 | <0.08 | <0.06 | <0.05 | <0.03 |

| Tg Glass Transition Temp. (°C) |

IPC-TM-650 2.4.25 | 130 | 130 | 150 | 180 | 180 | 180 | 180 |

| MOT Maximum Operation Temp. (°C) |

– | 130 | 130 | 150 | 180 | 180 | 180 | 180 |

| [AC KV/mm] Dielectric Breakdown Voltage | IPC-TM-650 2.5.6.2 | >20 | >30 | >25 | >20 | >15 | >30 | >20 |

| DC (KV/mm) Dielectric Breakdown Voltage |

IPC-TM-650 2.5.6.2 | >40 | >40 | >20 | >25 | >25 | >40 | >40 |

| Volume Resistivity (Ω·cm) | IPC-TM-650 2.5.17.1 | 1.5×1015 | 2.0×1015 | 2.0×1015 | 2.0×1015 | 3.0×1017 | 1.0×1018 | 1.0×1016 |

| Surface Resistivity (Ω) | IPC-TM-650 2.5.17.1 | 4.25×1013 | 4.25×1013 | 4.25×1013 | 4.25×1013 | 3.0×1016 | 1.0×1018 | 1.0×1013 |

| (kg/cm) Copper Peel Strength @1oz Cu |

IPC-TM-650 2.4.8 | >1.4 | >1.4 | >1.3 | >1.2 | >1.2 | >1.0 | >0.8 |

| (Min) T288, floating on solder |

JIS C 6481 | >10 | >10 | >10 | >5 | >10 | >10 | >10 |

| (°C) Thermal Decomposition Temp (2%) |

ASTM D 3850 | 350 | 350 | 350 | 350 | 350 | 400 | 380 |

| (°C) Thermal Decomposition Temp (5%) |

ASTM D 3850 | 410 | 410 | 410 | 410 | 410 | 450 | 430 |

| CTE (Coefficient of Thermal Expansion) below Tg [PPM/°C] Thermal Expansion | IPC-TM-650 2.4.24 | 75 | 55 | 55 | 55 | 55 | 53 | 48 |

| CTE (Coefficient of Thermal Expansion) above Tg [PPM/°C] Thermal Expansion | IPC-TM-650 2.4.24 | 300 | 60 | 60 | 33 | 33 | 33 | 30 |

| CTI (V) Comparative Tracking Index |

UL 746 | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

| Flammability, UL-94, Class | UL 94 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 |

| (Dk) Dielectric Constant, 1GHz |

IPC-TM-650 2.5.5.9 | 4.68 | 4.68 | 6.6 | 6.6 | 4.8 | 4.8 | 4.4 |

| (Df) Dissipation Factor, 1GHz |

IPC-TM-650 2.5.5.9 | 0.013 | 0.013 | 0.018 | 0.020 | 0.016 | 0.015 | 0.012 |

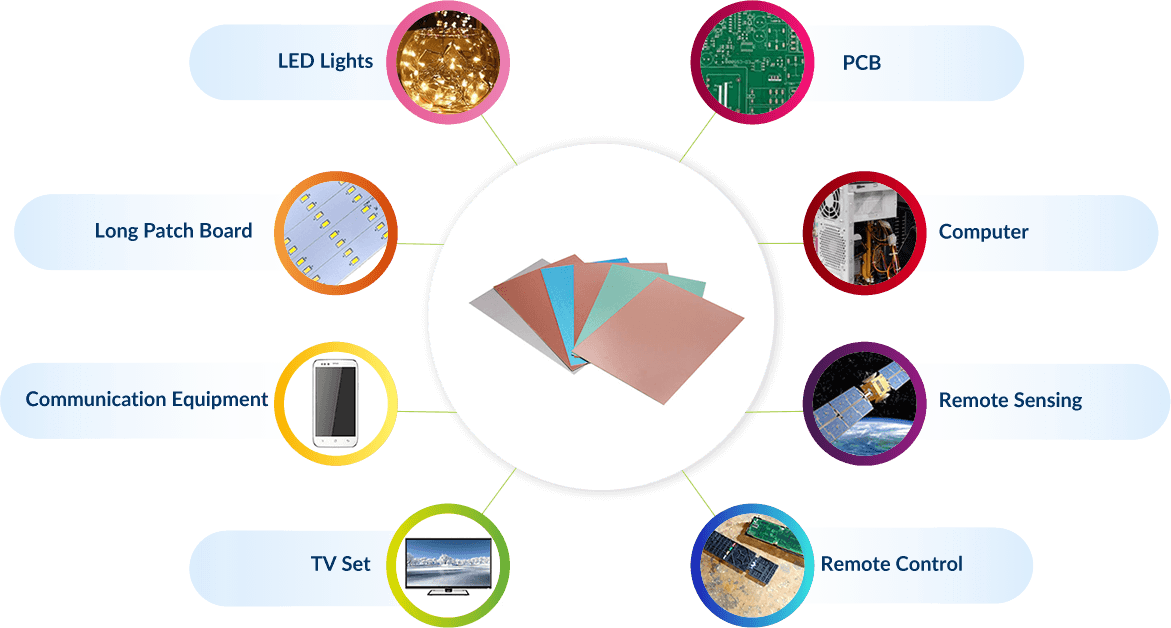

Product Application

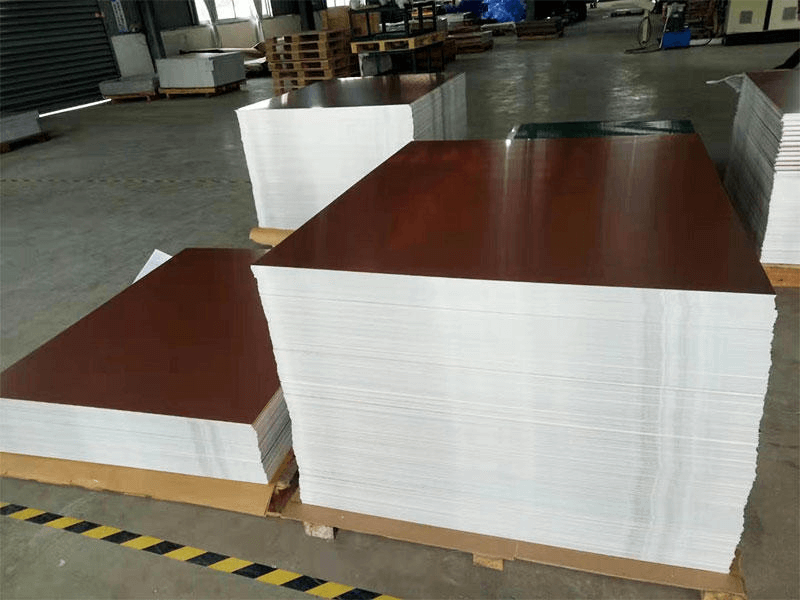

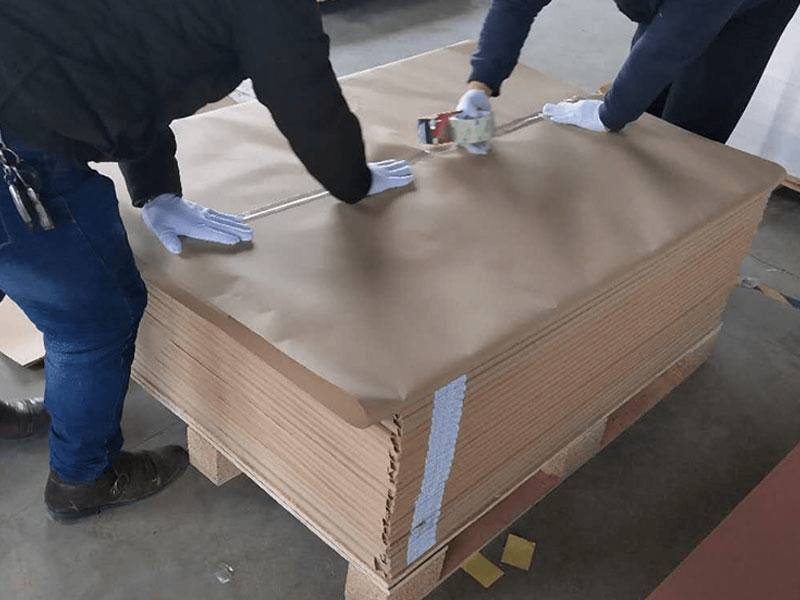

Product Packaging

More Products Information

The Science Behind Aluminum PCB Insulation’s Superior Performance

Unlock the secrets of aluminum PCB insulation: boosting thermal performance and reliability in your electronic devices.

What is Aluminum Copper Clad Laminate

Discover Aluminum Copper Clad Laminate (ACCL): the essential material enabling faster, cooler, and lighter electronics for today's tech.

Applications of Aluminum Copper Clad Laminate

Learn how Aluminum Copper Clad Laminate powers electronics, EVs, 5G, aerospace, and more, thanks to its thermal, shielding & strength benefits.